In a market full of specialised sailing hardware, it is unusual to find a piece of equipment that is genuinely unique. The Spinlock BRS mobile jamming block is one of those rare items — a deceptively simple, highly practical solution to a well-known problem on sailing yachts: creating a reliable turning point with temporary load control, exactly where it is needed, without drilling holes or committing to a fixed deck layout.

Spinlock is well known for its work in rope-handling systems — clutches, jammers, cleats, deck organisers — so it is no surprise that the Spinlock BRS is engineered around the realities of modern line control. It sits quietly within their catalogue, but once its purpose and versatility are understood, it becomes clear why many sailors keep one aboard as a problem-solving tool.

What Is the Spinlock BRS?

The Spinlock BRS is a mobile block with an integrated three-mode cam, supplied with its own webbing strop. Spinlock describe it as a solution “for situations where a fixed foot block can’t help: peeling spinnakers, or changing a sheet winch.” These are exactly the moments when sailors need a new lead — instantly, securely, and without adding permanent hardware.

The flexible strop is central to the concept. Instead of relying on bolts or shackles, the BRS can be looped around toe rails, padeyes, stanchion bases, boom sections, or other appropriate strong points. Once in place, the block articulates freely to align with the sheet angle — essential for spinnaker work and dynamic loads.

Two sizes are available, Spinlock BRS 50 mm and Spinlock BRS 63 mm, both using the same operating mechanism and fulfilling the same purpose. Installation is fast, tool-free, and reversible.

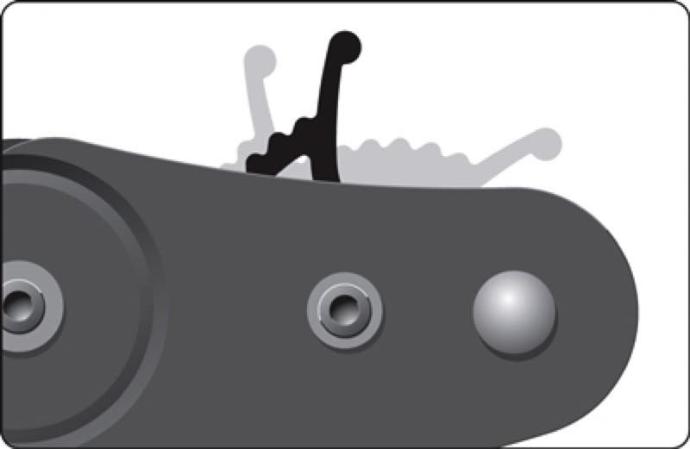

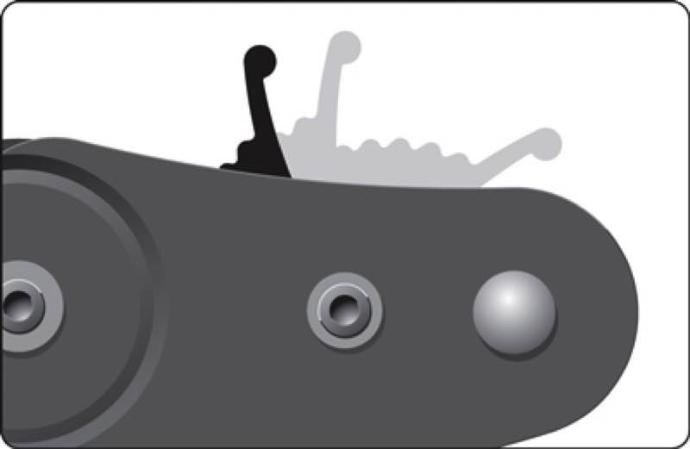

At the centre of its functionality is the cam, which offers three operating modes:

• Lock-back – the cam is held fully open and clear of the rope.

• Auto-release – when the line loads, the cam automatically opens to allow smooth running.

• Friction mode – when load is eased, the cam rests on the rope and provides temporary holding power up to around 20% of the block’s SWL.

Lock Back

Auto Release

Friction Mode

This means the Spinlock BRS is not just a turning block — it acts as a compact, mobile jammer.

Why Sailors Use the Spinlock BRS

Spinlock BRS for Spinnaker Peeling

A spinnaker peel is one of the most demanding manoeuvres on a yacht, requiring clean, well-controlled line management. Crews often need an additional turning point on the toe rail or near the shrouds to fairlead a temporary sheet. The Spinlock BRS can be positioned within seconds, rotates freely with the load, and provides a controlled sheet path at exactly the required angle.

Using the Spinlock BRS for New or Alternative Sheet Leads

When experimenting with new deck layouts or trim geometries, sailors frequently need to trial alternative sheet leads. The BRS is ideal for this: attach it, run the sheet, evaluate, and reposition as needed. Cruisers appreciate being able to do this without drilling or committing to a new fitting.

Changing a Sheet Winch

When a winch is overloaded or temporarily required for another job, the BRS provides a quick redirect. By parking the sheet in friction mode, a primary winch can be freed up long enough to reorganise the cockpit without losing control.

Spinlock BRS for Emergency or Temporary Rigging

If a fixed block or organiser fails, the Spinlock BRS can serve as an instant replacement. As long as the strop is secured around a suitable smooth, radius-friendly strong point, it provides a dependable temporary lead — a useful backup for offshore sailors.

Durability and Load Behaviour of the Spinlock BRS

Although the BRS appears simple, its construction is designed for the realities of running spinnaker sheets. The plain-bearing sheave operates efficiently under light loads and tolerates heavy or shock loads well. The cam is deliberately not designed to take full sheet loads — it is a temporary holding aid, not a clutch — but within that role it performs effectively.

Maintenance is straightforward: rinse with fresh water, avoid abrasive surfaces and harsh chemicals, and apply silicone-based lubricant or Spinlock grease when dry.

Why the Spinlock BRS Remains a Valuable On-Board Tool

The Spinlock BRS addresses a specific set of real sailing challenges. Whether racing with asymmetric spinnakers, coastal cruising, or wanting a flexible deck layout without adding permanent fittings, the Spinlock BRS offers a well-engineered, reliable solution.

For many sailors, it is a small item that delivers significant value — and carrying one (or a spare strop) on board remains a smart choice.

Spinlock BRS – A Technical Overview of the Mobile Jamming Block