For many sailing yacht owners, the question is no longer whether to use Dyneema®, but which grade to choose. In modern sailing applications, Dyneema SK78 and Dyneema SK99 dominate the discussion, particularly for halyards and other load-critical running rigging.

At first glance, Dyneema SK99 appears to be the obvious upgrade: stronger, stiffer and capable of further diameter reduction. In practice, however, the choice between SK78 and SK99 is more nuanced. Creep behaviour, diameter selection, hardware compatibility and long-term stability often matter more than headline strength figures.

This article provides a technical comparison of Dyneema SK78 and SK99, explains common specification pitfalls, and offers clear guidance on when Dyneema SK99 delivers real benefits — and when it does not.

A Common Specification Problem: “Dyneema®” Without a Grade

Before comparing SK78 and SK99 directly, it is important to address how Dyneema® is often specified.

When a rope description refers simply to “Dyneema®” without stating a fibre grade, this almost always indicates Dyneema SK75. SK75 remains widely available and cost-effective, but it has significantly poorer creep resistance than SK78 or SK99.

For applications where long-term dimensional stability matters — particularly halyards left under tension — the absence of a stated SK grade should be treated as meaningful information rather than a harmless omission. If creep performance matters, the grade should always be specified explicitly.

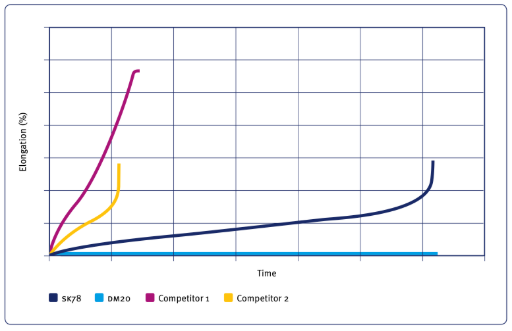

Figure 1 (creep behaviour over time) provides a clear visual reference for why this distinction matters in practice (Source DSM Dyneema®).

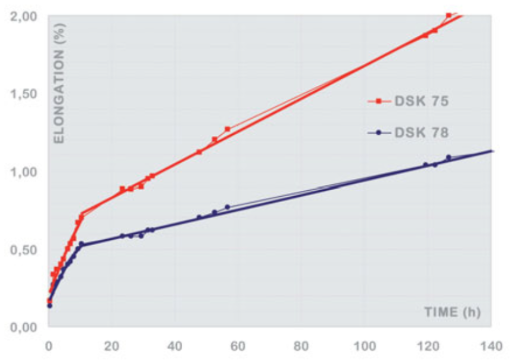

Figure 2: Creep comparison between Dyneema SK75 and SK78, at 25°C and at an average static load equal to approximately 25% of the breaking strength. The graph shows that Dyneema SK78 has a creep rate that is about 3 times slower than SK75. (Source Gottifredi Maffioli

Baseline Material Differences: Dyneema SK78 vs Dyneema SK99

At a fibre level, the key differences between Dyneema SK78 and Dyneema SK99 can be summarised as follows:

- SK99 offers higher tensile strength than SK78

- SK99 has a higher modulus, resulting in lower elastic stretch

- SK99 enables smaller diameters for a given breaking load

- SK99 provides improved creep resistance, but not zero creep

SK78, by contrast, is designed to balance:

- Strength and creep resistance

- Predictable long-term behaviour

- Greater tolerance of real-world sailing hardware

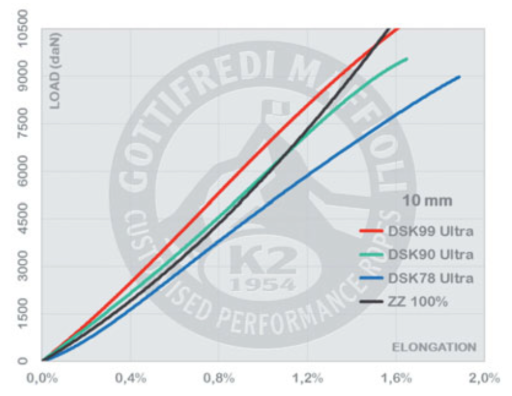

These differences are best understood visually. Figure 2 (stress–strain comparison) illustrates the higher modulus of Dyneema SK99 and explains why it feels noticeably stiffer under load.

Creep Behaviour: What the Data Shows

Creep is often cited as a reason to “upgrade” from Dyneema SK78 to Dyneema SK99, but the improvement is frequently misunderstood.

Both SK78 and SK99 were developed to address the creep limitations of Dyneema SK75. SK99 does show lower long-term elongation under sustained load than SK78, but the improvement is incremental rather than transformational.

As shown in Figure 3 (Courtesy of Gottifredi Maffioli), creep is reduced as fibre technology improves, but it is not eliminated. Under sustained load, both Dyneema SK78 and SK99 will exhibit permanent elongation over time, particularly as working load percentage increases.

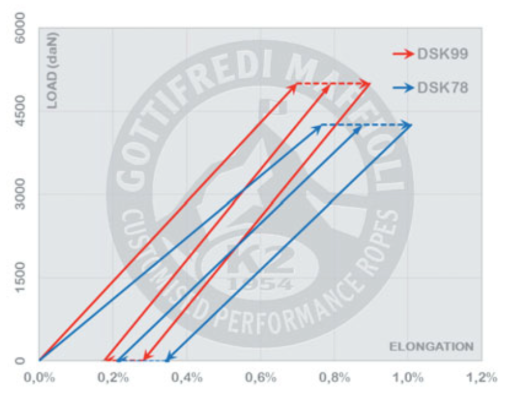

Figure 4 (Courtesy of Gottifredi Maffioli) Comparison of visco-elasticity of Dyneema SK99 and SK78. Samples of equal diameter were loaded to 50% of their breaking strength for 1h and tested again after 1h of rest. The DSK99 shows a lower visco-elastic elongation.

This distinction matters because creep performance is strongly influenced by how the rope is specified and used, not just by fibre grade.

Diameter Reduction: Benefit or Trap?

The primary attraction of Dyneema SK99 in sailing applications is the ability to reduce diameter.

A smaller-diameter halyard:

- Reduces weight aloft

- Runs more efficiently through sheaves

- Can improve clutch holding at high loads

However, reducing diameter increases the percentage of breaking load carried in service, which accelerates creep in all UHMWPE fibres.

For this reason, many experienced riggers specify Dyneema SK99 at the same diameter as Dyneema SK78, using the additional strength margin to:

- Reduce working load percentage

- Improve long-term dimensional stability

- Extend service life

This approach delivers measurable benefits. Simply downsizing does not.

Dyneema SK99 Rope

Working Load Percentage and Long-Term Stability

Creep behaviour in UHMWPE fibres is driven primarily by sustained load expressed as a percentage of breaking strength, rather than fibre grade alone. This distinction is critical to understanding why some Dyneema® lines remain dimensionally stable for many years, while others show noticeable long-term elongation.

Engineering guidance for Dyneema® indicates that, for non-critical applications, working loads in the region of 11% to 20% of published breaking load generally result in very low, predictable creep. Within this range, long-term elongation can be accommodated in design and is often negligible in practical sailing use.

As sustained load increases, creep accelerates rapidly. When UHMWPE fibres are exposed to prolonged loads approaching 30% of breaking load, creep becomes significant and can ultimately limit service life. In sailing systems, this situation most commonly arises when ropes are aggressively downsized to minimise diameter, unintentionally increasing the working load carried in service.

At appropriate working loads, fibres such as Dyneema SK78 exhibit stable, predictable behaviour suitable for long-term use in running rigging. Higher-modulus fibres like SK99 can improve stiffness and reduce diameter, but only when diameter reduction is approached conservatively. Using Dyneema SK99 purely to downsize often negates its creep advantage.

Temperature further influences creep behaviour. Elevated temperatures — including local heating from clutches and sheaves — accelerate creep, while lower temperatures reduce it. This reinforces the importance of matching fibre choice, diameter, cover construction and deck hardware as a complete system.

For sailing applications, long-term stability is achieved not by chasing the highest-modulus fibre, but by controlling sustained load, managing heat and selecting realistic diameters. These factors matter more than fibre grade alone.

Handling, Fatigue and Hardware Interaction

SK99’s higher modulus makes it stiffer and less forgiving than SK78.

In sailing systems, this can result in:

- Reduced grip in some rope clutches

- Greater sensitivity to tight bend radii

- Increased importance of cover construction and material choice

Dyneema SK78 Ropes

When Dyneema SK99 Makes Sense

Dyneema SK99 is well suited to sailing applications where:

- Loads are high relative to available diameter

- Weight aloft is a primary concern

- Deck hardware is optimised for high-modulus lines

- Rig tuning precision is critical

Typical examples include:

- Performance halyards on race-oriented yachts

- High-load running backstays

- Optimised performance cruising rigs

In these cases, SK99 can deliver meaningful benefits when specified conservatively and paired with appropriate covers and hardware.

When NOT to Use Dyneema SK99

SK99 is often a poor choice when:

- The primary objective is cost reduction

- Hardware is marginal or not designed for stiff fibres

- Diameter is reduced aggressively to chase weight savings

- The application is highly dynamic rather than load-critical

For many cruising yachts, Dyneema SK78 offers a better balance of:

- Predictable creep behaviour

- Handling comfort

- Hardware compatibility

- Cost efficiency

In these applications, SK99 may increase complexity without delivering meaningful real-world advantages.

Final Guidance for Sailors

Dyneema SK99 is not “better Dyneema®” in all cases. It is a higher-modulus, higher-strength fibre that rewards careful specification and punishes shortcuts.

For most cruising yachts:

- Dyneema SK78 remains the most balanced choice for halyards and running rigging

For performance-oriented systems:

- Dyneema SK99 can deliver real advantages, provided diameter reduction is approached conservatively

And whenever a specification simply states “Dyneema®” without identifying an SK grade, it should be assumed that SK75 is being used, with all the associated creep implications.

The figures referenced throughout this article illustrate a consistent theme: long-term performance is defined not by fibre choice alone, but by how strength, diameter and sustained load interact in real sailing systems.

Dyneema SK78 vs Dyneema SK99: A Technical Comparison for Sailing Ropes